Our research centers on the design and development of functional organic/inorganic nanocomposites and biomaterials, focusing on their physical and chemical property characterizations. Our work involves the characterization of physical properties of polymers and soft matter used in diverse industries, aiming to understand and replicate their unique physicochemical behaviors through the engineering of filler/matrix interfaces. We are studying various types of acrylic and epoxy-based debond-on-demand adhesives, as well as battery cover films with fire-retardant capabilities to enhance the recyclability of batteries and prevent catastrophic fire accidents for electric vehicles. We also design programmable materials inspired by nature, such as unique hierarchical systems found in hair or bone. One example is the load-induced fluid flow systems and vascular architectures that mimic the lacunar-canalicular network in bone. We employ interdisciplinary methods based on mechanical, chemical, physical, and materials science knowledge, including material property characterizations, computations (molecular dynamics simulations, machine learning, parametric modeling, etc.), and advanced fabrication technology (3D printing and robotic experimentation) to explore the relationships between external environments and internal architectures. Another example is the study of applying biogenic materials, like beeswax, as sustainable alternatives to conventional light fixtures, integrating materials design with sustainability. Advancing programmable metamaterials through machine learning-driven buckling strength optimization is also among our very interesting research topics. Our group emphasizes the convergence of materials physics, engineering, and design to develop innovative solutions in mechanical engineering.

1. Covalent organic frameworks-based nanocomposites

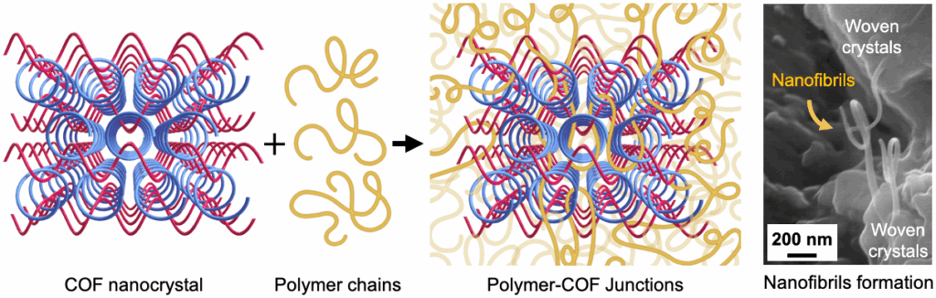

3D woven covalent organic frameworks (COFs) template polymer chains, forming entangled junctions that facilitate nanofibril formation under stress. In this study, we used various types of COFs as nanofillers and embedded them into a polymeric matrix to achieve mechanically reinforced nanocomposites, which can improve stiffness, strength, and toughness simultaneously—properties that are mutually exclusive.

- Keywords: covalent organic frameworks, nanocomposites, polymer-COF junctions, mechanical properties

2. Debond-on-demand adhesives for electric vehicles

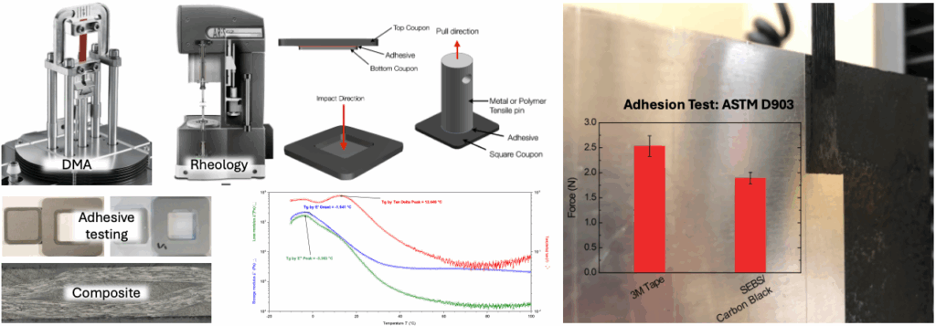

With the commercialization of electric vehicles, environmental issues arising from waste batteries have emerged, highlighting the importance of waste battery recycling technology. However, electric vehicle batteries are firmly fixed to the vehicle structure with adhesives, making their removal difficult. To address this problem, debond-on-demand technology—which allows adhesives to be separated at the desired time—is being applied to adhesives. While methods that apply heat are generally used, batteries are vulnerable to heat and are bulky and heavy, so mechanical or electrical methods are being considered. In this study, we research debond-on-demand adhesives for automotive battery recycling, aiming for commercialization through process optimization.

- Keywords: debond-on-demand, adhesive, PSA, epoxy, electric vehicle, sustainability, battery recycle

3. Structure-property relations established using computations (DFT, molecular dynamics, machine learning)

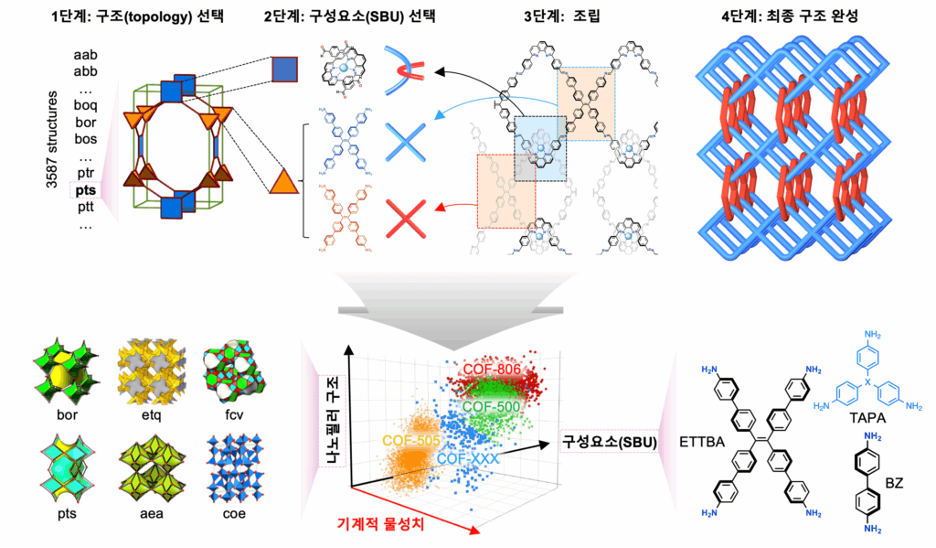

This research aims to compile mechanical property data of crystal structures using molecular dynamics (MD) simulations and employ machine learning to develop an AI-based tool for crystal structure design and engineering. The AI tool will select appropriate topologies and secondary building units (SBUs) based on mechanical properties. By performing MD simulations on unit cells with minimal atom counts under static conditions (eliminating the time variable), we can accelerate calculations and accurately obtain mechanical properties, such as stiffness, without surface effects. The method involves applying strain to the periodic boundary condition (PBC) box to analyze tensile/compression and normal/shear behaviors, and conducting molecular statics simulations to study crack propagation, dislocations, relaxation, defect energetics, and modulus. We will provide a “COF Database” containing mechanical property information for various topologies (up to 2,495) and SBUs (up to 279), encompassing millions of combinations, including 5,856 two-dimensional and 262,831 three-dimensional structures, along with properties like mass density, accessible surface area, pore fraction, and other mechanical properties. The force field creation process involves four steps: First, selecting the appropriate topology from the RCSR (rcsr.net) library. Second, generating structures and potentials for individual building block units using tools like LigParGen, which automatically creates force fields for organic molecules or ligands. Third, assembling the building units into the selected topology without bonding them. Finally, forming the final structure by bonding the building units together.

- Keywords: crystal structures, molecular dynamics, force fields, topology, mechanical properties

4. Beeswax luminaires

Biogenic materials are essential for sustainable manufacturing to reduce environmental footprints. This study proposes the “Beeswax Luminaires”, a user-friendly, non-toxic, and customizable production technique for designing with waxes. Beeswax Luminaires utilize naturally sourced materials—water and beeswax—to achieve a more sustainable lighting solution. They are designed through a multi-disciplinary collaboration involving materials science, computational design, and robotic fabrication. Chemical, thermal and mechanical properties of beeswax are characterized prior to the design and fabrication processes. Parametric modeling is used to create optimized designs and an adaptable production flow. Robotically fabricated samples of two designs are compared for defects, compressive strength, and light diffusion. By understanding the physical properties of beeswax and incorporating digital modeling and fabrication, Beeswax Luminaires achieve optimization, scalability, and sustainability in design and manufacturing.

- Keywords: beeswax, biomaterials, lighting design, computational design, robotic fabrication, sustainability